Cavity expansion methods for cast in-situ piles¶

- groundhog.deepfoundations.boreholestability.cavityexpansion.expansion_cylinder_tresca(insitu_pressure, borehole_pressure, diameter, undrained_shear_strength, shear_modulus, poissons_ratio=0.5, max_radius_multiplier=10.0, number_radii=250, **kwargs)[source]¶

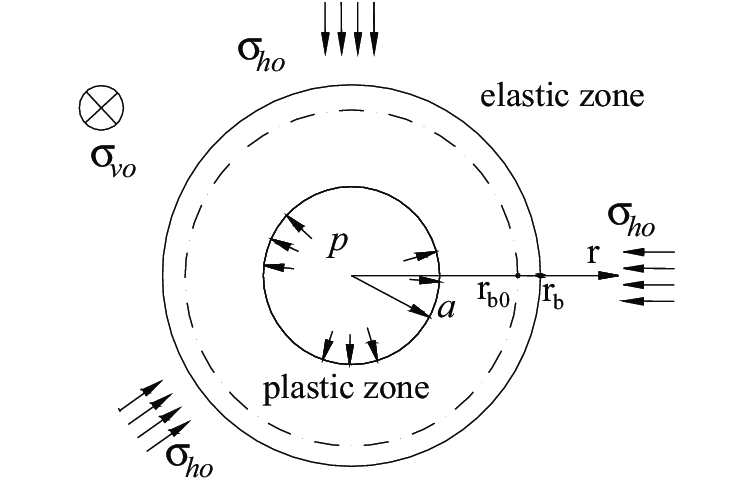

Calculates the cavity expansion for a cylinder in Tresca material. The relation between borehole radius + plastic radius and pressure differential is calculated first.

This relation is then used to evaluate where the imposed pressure lies, whether it causes any plasticity around the borehole and whether it does not cause overall borehole failure.

The stresses for the given pressure are then calculated.

- Parameters:

insitu_pressure – Isotropic horizontal stress in the soil mass before borehole excavation (\(p_0\)) [\(kPa\)] - Suggested range: insitu_pressure >= 0.0

borehole_pressure – Pressure on the borehole wall due to drilling fluids or concrete (\(p\)) [\(kPa\)] - Suggested range: borehole_pressure >= 0.0

diameter – Borehole initial diameter (equations are formulated in terms of radius but diameter is more convenient as input) (\(2 \cdot a_0\)) [\(m\)] - Suggested range: diameter >= 0.0

undrained_shear_strength – Undrained shear strength of the material surrounding the borehole (\(S_u\)) [\(kPa\)] - Suggested range: undrained_shear_strength >= 0.0

shear_modulus – Shear modulus of the material surrounding the borehole (\(G\)) [\(kPa\)] - Suggested range: shear_modulus >= 0.0

poissons_ratio – Poissons ratio of the material surrounding the borehole (default for undrained material)) (\(\nu\)) [\(-\)] - Suggested range: 0.0 <= poissons_ratio <= 0.5 (optional, default= 0.5)

max_radius_multiplier – Multiplier on borehole radius for determining the maximum extent of the calculation (:math:``) [\(-\)] - Suggested range: max_radius_multiplier >= 1.0 (optional, default= 10.0)

number_radii – Number of radii considered for the calculation (:math:``) [\(-\)] (optional, default= 250)

\[ \begin{align}\begin{aligned}\text{Elastic properties}\\n = \frac{4 \cdot S_u \cdot (1 - \nu^2) }{E}\\E = 2 \cdot G \cdot (1 + \nu)\\\text{Plastic radius and wall radius expansion during plastic deformation}\\\left( \frac{c}{a} \right)^2 = \left( \frac{a_0}{a} \right)^2 + \frac{1}{n} \cdot \left[ 1 - \left( \frac{a_0}{a} \right)^2 \right]\\\frac{p - p_0}{2 \cdot S_u} = \frac{1}{2} + \frac{1}{2} \cdot \ln \left[ \frac{G}{S_u} \cdot \left( 1 - \left( \frac{a_0}{a} \right)^2 \right) + \left( \frac{a_0}{a} \right)^2 \right]\\\text{Elastic stresses and displacements can be calculated by taking the limit for the outer radius going to infinity}\\\sigma_r = - p_0 - (p - p_0) \cdot \frac{\frac{b_0^2}{r^2} - 1}{\frac{b_0^2}{a_0^2} - 1} \implies \sigma_r = -p_0 - (p - p_0) \cdot \frac{a_0^2}{r^2}\\\sigma_{\theta} = -p_0 + (p - p_0) \cdot \frac{\frac{b_0^2}{r^2} + 1}{\frac{b_0^2}{a_0^2} - 1} \implies \sigma_{\theta} = -p_0 + (p - p_0) \cdot \frac{a_0^2}{r^2}\\u = \frac{(1 + \nu) \cdot (p - p_0)}{E} \cdot \frac{a_0^2}{b_0^2 - a_0^2} \cdot \left[ (1 - 2 \cdot \nu) \cdot r + \frac{b_0^2}{r} \right] \implies u = \frac{(1 + \nu) \cdot (p - p_0)}{E} \cdot \frac{a_0^2}{r}\\\text{The plasticity critertion can be expressed as:}\\\sigma_{r,r=a_0} - \sigma_{theta,r=a_0} = 2 \cdot S_u \implies -(p - p_0) = S_u\\\text{The elastic stresses and displacements outside of the plastic zone can be written as:}\\\sigma_r = -\frac{S_u \cdot c^2}{b_0^2} \cdot \left( \frac{b_0^2}{r^2} - 1 \right) - p_0 \implies \sigma_r = -\frac{S_u \cdot c^2}{r^2} - p_0\\\sigma_{\theta} = \frac{S_u \cdot c^2}{b_0^2} \cdot \left( \frac{b_0^2}{r^2} + 1 \right) - p_0 \implies \sigma_{\theta} = \frac{S_u \cdot c^2}{r^2} - p_0\\u = \frac{(1 + \nu) \cdot S_u \cdot c^2}{E \cdot b_0^2} \cdot \left[ (1 - 2 \cdot \nu) \cdot r + \frac{b_0^2}{r} \right] \implies u = \frac{(1 + \nu) \cdot S_u \cdot c^2}{E} \cdot \frac{1}{r}\\\text{Stresses in the plastic zone:}\\\sigma_r = -p_0 - S_u - 2 \cdot S_u \cdot \ln \left( \frac{c}{r} \right)\\\sigma_{\theta} = -p_0 + S_u - 2 \cdot S_u \cdot \ln \left( \frac{c}{r} \right)\end{aligned}\end{align} \]- Returns:

Dictionary with the following keys:

’yielding’: Boolean determining whether plastic deformation is taking place or not

’pressure expansion function’: Dictionary with the pressure-expansion relation with keys expansion [m] and pressure difference [kPa]

’yielding pressure [kPa]’: Borehole pressure at which yield occurs [\(kPa\)]

’radii [m]’: Numpy array with radii used for the stress and displacement calculation [\(m\)]

’radial stresses [kPa]’: Numpy array with the radial stresses around the borehole [\(kPa\)]

’tangential stresses [kPa]’: Numpy array with the tangential stresses around the borehole [\(kPa\)]

’elastic wall expansion [m]’: Borehole elastic wall expansion [\(m\)]

’plastic wall expansion [m]’: Borehole plastic wall expansion (\(a - a_0\)) [\(m\)]

’plastic radius [m]’: Radius of the plastic zone (\(c\)) [\(m\)]

Reference - Yu, H.-S., 2000. Cavity Expansion Methods in Geomechanics. Springer-Science+Business Media, B.V.

- groundhog.deepfoundations.boreholestability.cavityexpansion.expansion_tresca_thicksphere(undrained_shear_strength, internal_radius, external_radius, internal_pressure, external_pressure, youngs_modulus, poissons_ratio, seed=100, **kwargs)[source]¶

Calculates the stresses for cavity expansion around a thick-walled sphere in Tresca material.

The plastic radius is first calculated from the pressure boundary conditions. Using this plastic radius, the stresses in the elastic and plastic region are calculated.

- Parameters:

undrained_shear_strength – Undrained shear strength of the material surrounding the spherical cavity (\(S_u\)) [\(kPa\)] - Suggested range: undrained_shear_strength >= 0.0

internal_radius – Initial internal radius of the spherical cavity (\(a_0\)) [\(m\)] - Suggested range: internal_radius >= 0.0

external_radius – Initial external radius of the region (\(b_0\)) [\(m\)] - Suggested range: external_radius >= 0.0

internal_pressure – Internal pressure applied on the inside of the sphere (\(p\)) [\(kPa\)] - Suggested range: internal_pressure >= 0.0

external_pressure – External pressure on the outside of the sphere (\(p_0\)) [\(kPa\)] - Suggested range: external_pressure >= 0.0

youngs_modulus – Young’s modulus of the material (\(E\)) [\(kPa\)] - Suggested range: youngs_modulus >= 0.0

poissons_ratio – Poisson’s ratio of the material (\(\nu\)) [\(-\)] - Suggested range: 0 <= poissons_ratio <= 0.5

seed – Number of radii at which stresses and displacements are calculated (:math:``) [\(-\)] (optional, default= 100)

\[ \begin{align}\begin{aligned}\text{Elastic solutions}\\\sigma_r = -p_0 - (p - p_0) \frac{\left( \frac{b_0}{r} \right)^3 - 1}{\left( \frac{b_0}{a_0} \right)^3 - 1}\\\sigma_{\theta} = \sigma_{\phi} = -p_0 + (p - p_0) \frac{\frac{1}{2} \left( \frac{b_0}{r} \right)^3 - 1}{\left( \frac{b_0}{a_0} \right)^3 - 1}\\u = r - r_0 = \frac{p - p_0}{E} \frac{(1 - 2 \nu) r + \frac{(1 + \nu) b_0^3}{2 r^2}}{\left( \frac{b_0}{a_0} \right)^3 - 1}\\\text{Yield criterion}\\\sigma_1 - \sigma_3 = 2 \cdot S_u\\\text{Internal pressure for yielding } (\sigma_1 = \sigma_{\theta}, \sigma_3 = \sigma_r)\\p = p_{1y} = p_0 + \frac{4 \cdot S_u}{3} \left[ 1 - \left( \frac{a_0}{b_0} \right)^3 \right]\\\text{Displacement at internal and external boundaries}\\u |_{r=a_0} = \frac{2 \cdot S_u \cdot a_0}{E} \left[ \frac{2 \cdot (1 - 2 \nu) \cdot a_0^3 }{3 \cdot b_0^3} + \frac{1 + \nu}{3} \right]\\u |_{r=b_0} = \frac{2 \cdot S_u \cdot (1 - \nu) \cdot a_0 }{E \cdot b_0^2}\\\text{Stresses and displacements in the elastic region after yielding}\\\sigma_r = - \frac{4 \cdot S_u \cdot c^3}{3 \cdot b_0^3} \left[ \left( \frac{b_0}{r} \right)^3 - 1 \right] - p_0\\\sigma_{\theta} = \sigma_{\phi} = \frac{4 \cdot S_u \cdot c^3}{3 \cdot b_0^3} \left[ \frac{1}{2} \left( \frac{b_0}{r} \right)^3 + 1 \right] - p_0\\u = \frac{4 \cdot S_u \cdot c^3}{3 \cdot E \cdot b_0^3} \left[ (1 - 2 \nu) \cdot r + \frac{(1 + \nu) b_0^3}{2 \cdot r^2} \right]\\\text{Stresses in the plastic region}\\\sigma_r = - 4 \cdot S_u \cdot \ln \left( \frac{c}{r} \right) - \frac{4 \cdot S_u}{3} \left[ 1 - \left( \frac{c}{b_0} \right)^3 \right] - p_0\\\sigma_{\theta} = 2 \cdot S_u - 4 \cdot S_u \cdot \ln \left( \frac{c}{r} \right) - \frac{4 \cdot S_u}{3} \cdot \left[ 1 - \left( \frac{c}{b_0} \right)^3 \right] - p_0\\\text{The pressure required to generate a plastic radius is thus}\\p = 4 \cdot S_u \cdot \ln \left( \frac{c}{a} \right) + \frac{4 \cdot S_u}{3} \left[ 1 - \left( \frac{c}{b_0} \right)^3 \right] + p_0\\\text{Expansion of the boundary}\\\left( \frac{a}{a_0} \right)^3 = 1 + \frac{6 (1 - \nu) S_u c^3}{E \cdot a_0^3} - \frac{4 (1 - 2 \nu) S_u}{E} \left[ 3 \ln \left( \frac{c}{a_0} \right) + 1 - \left( \frac{c}{b_0} \right)^3 \right]\end{aligned}\end{align} \]- Returns:

Dictionary with the following keys:

’elastic radii [m]’: Radii at which elastic stresses are calculated

’elastic_radial_stress [kPa]’: Radial stresses for purely elastic deformation (\(\sigma_{r,elastic}\)) [\(kPa\)]

’elastic_tangential_stress [kPa]’: Tangential stresses for purely elastic deformation (\(\sigma_{\theta,elastic}\)) [\(kPa\)]

’elastic_radial_displacement [m]’: Radial displacement for purely elastic deformation (\(u_{elastic}\)) [\(m\)]

’yielding_pressure [kPa]’: Internal pressure which initiates yield (\(p_{1y}\)) [\(kPa\)]

’plastic_radius [m]’: Radius of the plastic zone for the given internal and external pressures (\(c\)) [\(m\)]

’elastoplastic_radii [m]’: Radii at which elastoplastic stresses are calculated (equal amount of point inside and outside the plastic radius)

’elastoplastic_radial_stress [kPa]’: Radial stresses for Tresca soil (\(\sigma_r\)) [\(kPa\)]

’elastoplastic_tangential_stress [kPa]’: Tangential stresses for Tresca soil (\(\sigma_{\theta}\)) [\(kPa\)]

’expanded_radius [m]’: Radius of the internal wall after expansion (\(a\)) [\(m\)]

Reference - Yu, H.-S., 2000. Cavity Expansion Methods in Geomechanics. Springer-Science+Business Media, B.V.

- groundhog.deepfoundations.boreholestability.cavityexpansion.stress_cylinder_elastic_isotropic(radius, internal_pressure, farfield_pressure, borehole_radius, shear_modulus=nan, **kwargs)[source]¶

Calculates the radial and tangential stress around a cylindrical borehole under internal pressure, in a soil mass with isotropic virgin stress conditions in the given plane

- Parameters:

radius – Radius or radii at which to calculate the stresses (float or NumPy array) (\(r\)) [\(m\)] - Suggested range: radius >= 0.0

internal_pressure – Internal pressure on the borehole (\(p\)) [\(kPa\)] - Suggested range: internal_pressure >= 0.0

farfield_pressure – Far-field pressure, equal to the virgin horizontal stress (\(p_0\)) [\(kPa\)] - Suggested range: farfield_pressure >= 0.0

borehole_radius – Radius of the borehole (\(a\)) [\(m\)] - Suggested range: borehole_radius >= 0.0

shear_modulus – Shear modulus used to calculate the radial displacement (\(G\)) [\(kPa\)] - Suggested range: shear_modulus >= 0.0 (optional, default=np.nan). If unspecified, radial displacements are not calculated

\[ \begin{align}\begin{aligned}\frac{d \sigma_{r}}{dr} + \frac{\left(\sigma_{r} - \sigma_{\theta} \right)}{r} = 0\\\begin{split}\sigma_r | _{r=a} = p \\ \sigma_r | _{r=a} = p_0\end{split}\\\sigma_{r} = p_0 + \left( p - p_0 \right) \cdot \left( \frac{a}{r} \right)^2\\\sigma_{\theta} = p_0 - \left( p - p_0 \right) \cdot \left( \frac{a}{r} \right)^2\end{aligned}\end{align} \]- Returns:

Dictionary with the following keys:

’radial stress [kPa]’: Radial stress at the specified radii (\(\sigma_r\)) [\(kPa\)]

’tangential stress [kPa]’: Tangential stress at the specified radii (\(\sigma_{\theta}\)) [\(kPa\)]

’radial displacement [m]’: Radial displacement (calculated if shear modulus is specified) (\(u\)) [\(m\)]

Basic sketch of the cavity expansion problem¶

Reference - Yu, H.-S., 2000. Cavity Expansion Methods in Geomechanics. Springer-Science+Business Media, B.V.